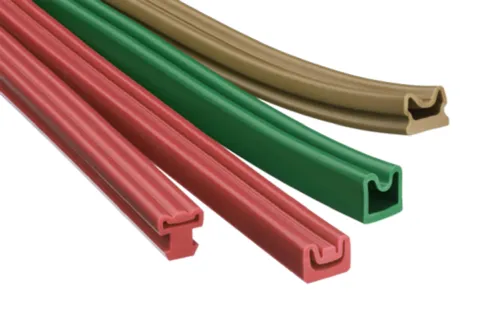

Rubber extrusions have become an essential component in various industries, offering a wide range of benefits including durability, resistance to chemicals and extreme temperatures, and cost-effectiveness. These versatile products are used in a variety of applications, from sealing and insulation to vibration isolation and decorative trim. In this article, we will explore the top 10 industries that are currently using rubber extrusions, highlighting their specific uses and benefits.

1. Automotive Industry

The automotive industry is one of the largest users of rubber extrusions. These products are used in various applications such as sealing and insulation, vibration isolation, and decorative trim. Rubber extrusions are used to create gaskets, seals, and O-rings that provide airtight and watertight seals, ensuring the integrity of vehicles. Additionally, rubber extrusions are used in the manufacturing of conveyor belts, which are essential for smooth and efficient material transportation.

2. Construction Industry

The construction industry also relies heavily on rubber extrusions. These products are used to create seals around doors and windows, providing insulation and enhancing energy efficiency in buildings. Rubber extrusions are also used in the manufacturing of roofing materials, such as EPDM rubber, which is resistant to extreme temperatures and chemicals.

3. Aerospace Industry

The aerospace industry relies heavily on Rubber Diaphragm to ensure the integrity and performance of aircraft and spacecraft. One of the primary applications is in sealing and insulation, where rubber extrusions are used to create gaskets, seals, and O-rings that provide airtight and watertight seals. These seals are crucial in maintaining the pressure and temperature conditions within the aircraft or spacecraft, ensuring the safety and effectiveness of the mission.

Rubber extrusions are also used in vibration isolation applications, where they help to reduce the transmission of vibrations and noise through the aircraft or spacecraft. This is particularly important in sensitive areas such as the cockpit or laboratory, where vibrations can compromise the performance of critical systems. Additionally, rubber extrusions are used in decorative trim applications, where they provide a durable and aesthetically pleasing finish to the aircraft or spacecraft.

By using rubber extrusions in these various applications, the aerospace industry can ensure the reliability and performance of its products. The unique properties of rubber extrusions, such as their resistance to extreme temperatures and chemicals, make them an ideal material for these demanding applications. As the aerospace industry continues to evolve and push the boundaries of innovation, the use of rubber extrusions is likely to remain a critical component in the development of new and advanced aircraft and spacecraft.

4. Medical Industry

The medical industry relies heavily on rubber extrusions to ensure the safety and effectiveness of medical procedures. One of the primary applications is in medical devices, where rubber extrusions are used to create seals and gaskets that provide a sterile environment. These seals are crucial in preventing contamination and ensuring the integrity of medical devices, such as syringes, catheters, and surgical instruments.

Rubber extrusions are also used in implantable devices, such as pacemakers, artificial joints, and dental implants. These products require a high level of precision and durability to ensure proper function and longevity. Rubber extrusions provide a reliable and consistent seal, ensuring that the implant remains secure and functional over time.

In addition to medical devices and implants, rubber extrusions are also used in medical equipment, such as hospital beds, wheelchairs, and medical carts. These products require durable and easy-to-clean surfaces, which rubber extrusions provide. By using rubber extrusions in these applications, the medical industry can ensure the safety and effectiveness of medical procedures, while also providing durable and reliable products that meet the high standards of the medical community.

5. Food Industry

The food industry is another significant user of rubber extrusions. These products are used in various applications such as food processing, packaging, and storage. Rubber extrusions are used to create seals and gaskets that prevent contamination and ensure the quality of food products.

6. Chemical Industry

The chemical industry is another sector that heavily relies on rubber extrusions. These products are used in various applications such as chemical processing, storage, and transportation. Rubber extrusions are used to create seals and gaskets that provide airtight and watertight seals, ensuring the safety and effectiveness of chemical processes.

7. Oil and Gas Industry

The oil and gas industry is another significant user of rubber extrusions. These products are used in various applications such as oil and gas processing, storage, and transportation. Rubber extrusions are used to create seals and gaskets that provide airtight and watertight seals, ensuring the safety and effectiveness of oil and gas operations.

8. Electrical Industry

The electrical industry is another sector that heavily relies on rubber extrusions. These products are used in various applications such as electrical insulation, vibration isolation, and decorative trim. Rubber extrusions are used to create seals and gaskets that provide electrical insulation. Ensuring the safety and effectiveness of electrical systems.

9. Furniture Industry

The furniture industry is another significant user of rubber extrusions. These products are used in various applications such as furniture manufacturing, upholstery, and decoration. Rubber extrusions are used to create seals and gaskets that provide airtight and watertight seals. Ensuring the durability and effectiveness of furniture.

10. Packaging Industry

The packaging industry is another sector that heavily relies on rubber extrusions and inflatable gaskets. These products are used in various applications such as packaging materials, seals, and gaskets. Rubber extrusions are used to create seals and gaskets that provide airtight and watertight seals. Ensuring the safety and effectiveness of packaged products. The versatility and reliability of these materials make them an essential component in the ever-evolving world of packaging.

In conclusion rubber extrusions are used in a wide range of industries. Offering a variety of benefits including durability, resistance to chemicals and extreme temperatures, and cost-effectiveness. These versatile products are used in various applications. From sealing and insulation to vibration isolation and decorative trim. By understanding the specific uses and benefits of rubber extrusions in different industries, manufacturers can better design and produce products that meet the needs of their customers.